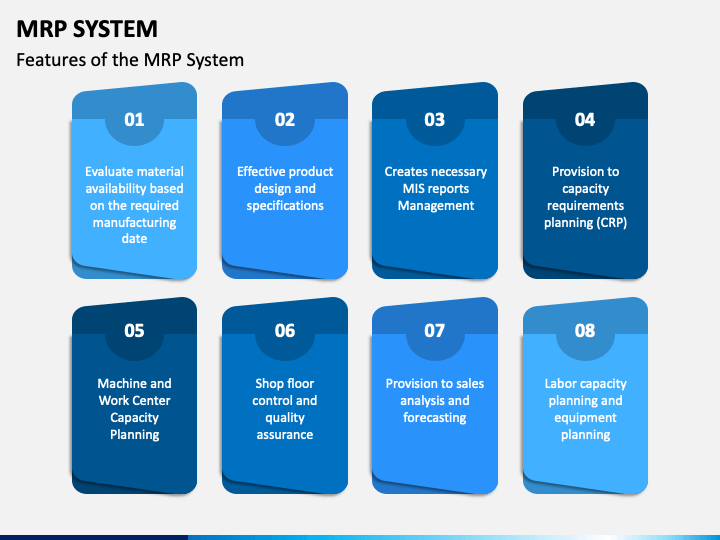

MRP is a logical easily understandable approach to the problem of determining the number of parts components and materials needed to produce each end item. MRP is an integral part of enterprise resource planning that ties together all the major functions of a firm.

Mrp Systems Seek To Achieve Which Of The Following

Mrp Systems Seek To Achieve Which Of The Following

Offering seamless management of production stock customers purchases finances and your team.

Mrp systems seek to achieve which of the following. To determine the amount of materials needed to produce each end item. Give immediate capacity relief D. Determine the number of dependent demand items needed C.

10 - 200 employees A simple yet powerful self-service manufacturing ERPMRP software. Cloud-based MRP system for small manufacturers. MRP Quality Maintenance and PLM.

Ad Product and Job Tracking Manufacturing Execution System-MES. Ad Replace your legacy system with dynamiccustomizable MRP software. MRP systems seek to achieve which of the following.

Relieve capacity bottlenecks D. Ad 1 QuickBooks Manufacturing Add-on Save Money and Try Free Today. Ad Replace your legacy system with dynamiccustomizable MRP software.

MRP and JIT materials resource planning and just in time processing are two methods of controlling production and inventory levels for manufacturers. MRP systems seek to achieve which of the following. 598 MRP systems seek to achieve which of the following.

Improve on JIT methods of capacity planning. MRP also provides the schedule specifying when each of these items should be ordered or produced. DProvide a yardstick for future improvements.

Plan capacity loading C. Provide a plan to maximize lot sizes B. Determine the number of dependent demand items needed Which of the following is mostly closely related to the reason a firm might implement MRP.

Ad Product and Job Tracking Manufacturing Execution System-MES. BDetermine the number of dependent demand items needed. MRP Quality Maintenance and PLM.

Provide a yardstick for future improvements E. All-in-one solution for your business. EImprove on JIT methods.

MRP systems seek to achieve which of the following. Minimize lot sizes B. Both MRP and JIT rely heavily on computerized information processing.

Provide a yardstick for future improvements E. All-in-one solution for your business. Material requirements planning is the key piece of logic that ties the production functions together from a material planning and control view.

MRP focuses on production of finished goods based on forecast requirements while JIT focuses on production as a response to actual orders. Improve on JIT methods MRP is based on dependent demand. Ad 1 QuickBooks Manufacturing Add-on Save Money and Try Free Today.

A master production schedule is an input to a material requirements planning MRP system. Opma Exam-2docx - 4 So they can order the right parts MRP systems seek to achieve which of the following 1The ability to rapidly and inexpensively.