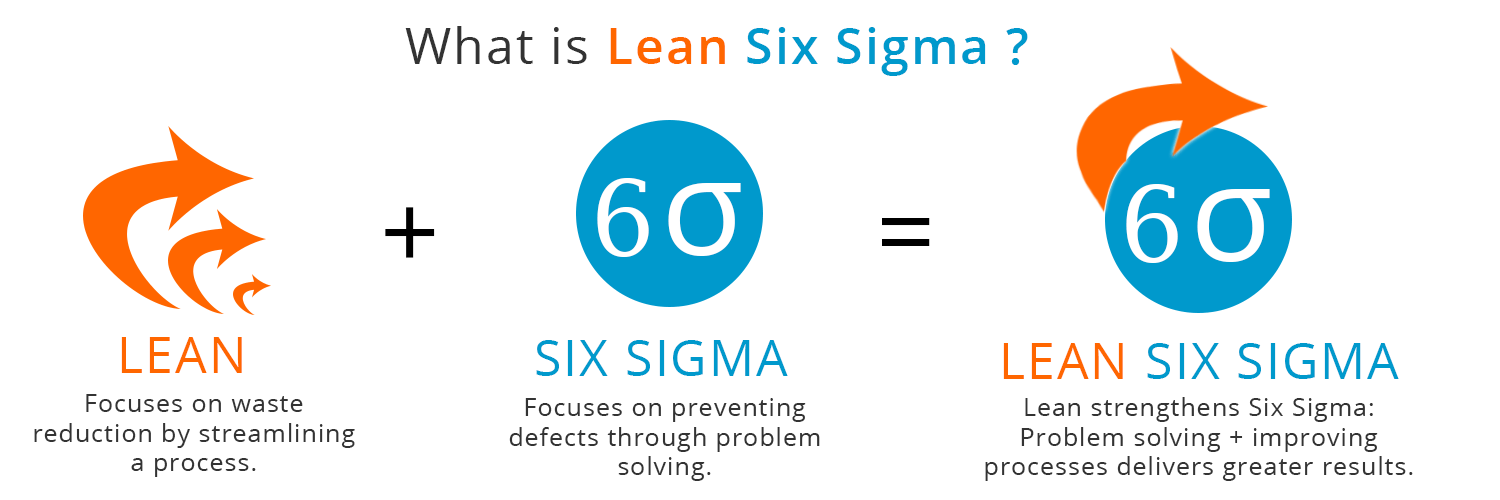

Lean Six Sigma is a process improvement methodology designed to eliminate problems remove waste and inefficiency and improve working conditions to provide a better response to customers needs. Perhaps you must improve customer satisfaction.

Together Lean Six Sigma is a methodology devised for a collaborative team effort to improve performance by systematically eliminating waste non-value adding activities and reducing variation.

What is lean 6 sigma. Lean Six Sigma is a management approach to improving the performance of a business. The objective is to use the power of both under one seamless delivery. Lean Six Sigma is a fact-based data-driven philosophy of improvement that values defect prevention over defect detection.

Lean 6 Sigma strives to eliminate the. Lean and Six Sigma are two process improvement methodologies which when used together become extremely powerful business transformational tools. Its sectioned into two different elements of Six Sigma and Lean.

Lean Six Sigma is one of the most relevant sets of tools and techniques for improving operations and processes. Lean six-sigma is well defined as a process improvement methodology that is mainly used to remove waste inefficiency eliminate hindrances and provide better customer requirements. Lean Six Sigma is a highly effective business management system focused on combining the efforts of the two concepts Lean and Six Sigma.

To better understand we must break up Lean and Six Sigma. Lean Six Sigma is a discipline that is used to help organizations deliver Customer Value through efficient operations and quality standards. As its name suggests the Lean Six Sigma method is the combination of principles of the Lean and Six Sigma methodologies which are known and recognized for their effectiveness.

Businesses all over Ireland are adopting Lean Six Sigma to maximise their organisations potential increase team morale and effectiveness and minimise waste and downtime. Lean six sigma is the amalgamation of 2 process improvement tools namely lean manufacturing and six sigma. Six Sigma on the other hand focuses on quality and consistency.

Professionals with a Lean Six Sigma qualification will understand how to make efficiency and quality improvements to the organization as effectively as possible. Lean Six Sigma is a methodology that focuses on improving business performance reducing costs and increasing efficiency and productivity. Together the lean six sigma practitioner can ensure that processes are highly efficient and agile using lean and of highly repeatable and consistent quality using.

I was fortunate to have been trained on Six Sigma by Motorola University and General Electric many years ago. It drives customer satisfaction and bottom-line results by reducing variation waste and cycle time while promoting the use of work standardization and flow thereby creating a competitive advantage. Lean focuses on efficiency through the minimization of waste errors and delays.

It combines tools and techniques methods and lean and six-sigma principles into a robust methodology to enhance organization performance. What is Lean 6 Sigma. Lean Six Sigma is a holistic approach to industrial management focused on improving performance by eliminating process waste Common examples of operational and maintenance OM waste include extra-processing inventory mismanagement transportation mismanagement non-utilized talent overproduction and equipment downtime.

In concrete terms it is the meeting between two methods of continuous improvement designed to increase the performance of the company. Maybe you need to increase the process throughput. It is done to improve and enhance the current processes and making them more inclined towards less wastage and mainly the lowering the amounts of defects.

Lean Six Sigma is a team-focused managerial approach that seeks to improve performance by eliminating waste and defects. Lean Six Sigma or Lean 6 Sigma LSS is the combination of 2 similar methodologies Lean and Six Sigma.

/Lean_Six_Sigma_Structure_Pyramid-671e13ecc9e84e6e922d961234f57124.png)

.jpg)