The lean six sigma method ensures high quality and customer satisfaction in the manufacturing. Lean Six Sigma is simply a process for solving a problem.

Six Sigma And Business Analytics Lean Six Sigma Analytics

Six Sigma And Business Analytics Lean Six Sigma Analytics

Establish the project a.

Six sigma lean process. In Japanese this translates to change for better but within the world of process improvement it has come to reflect a continuous iterative model for gradual change. The Deming Cycle Plan Do Study Act is the. Based on the Shewart cycle Plan Do Check Act.

6 Sigma focuses on reducing the variation within a process. Some more basics of Lean Process Improvement. The term sigma originates from the Greek language which refers to the standard deviation within a data set population.

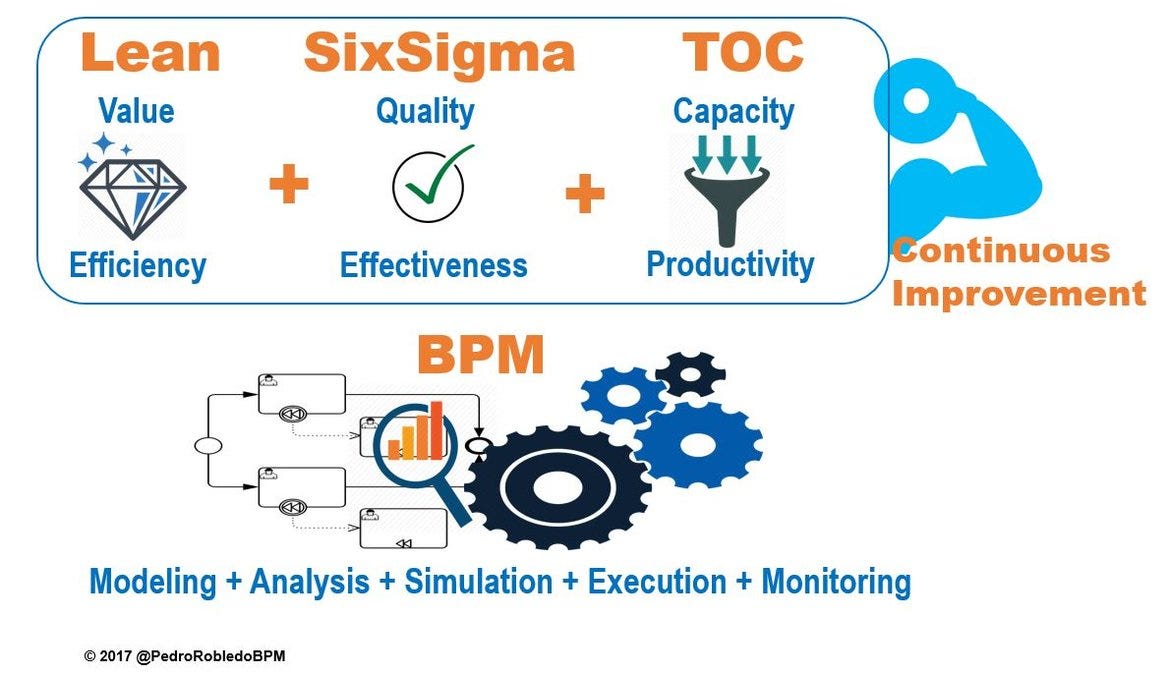

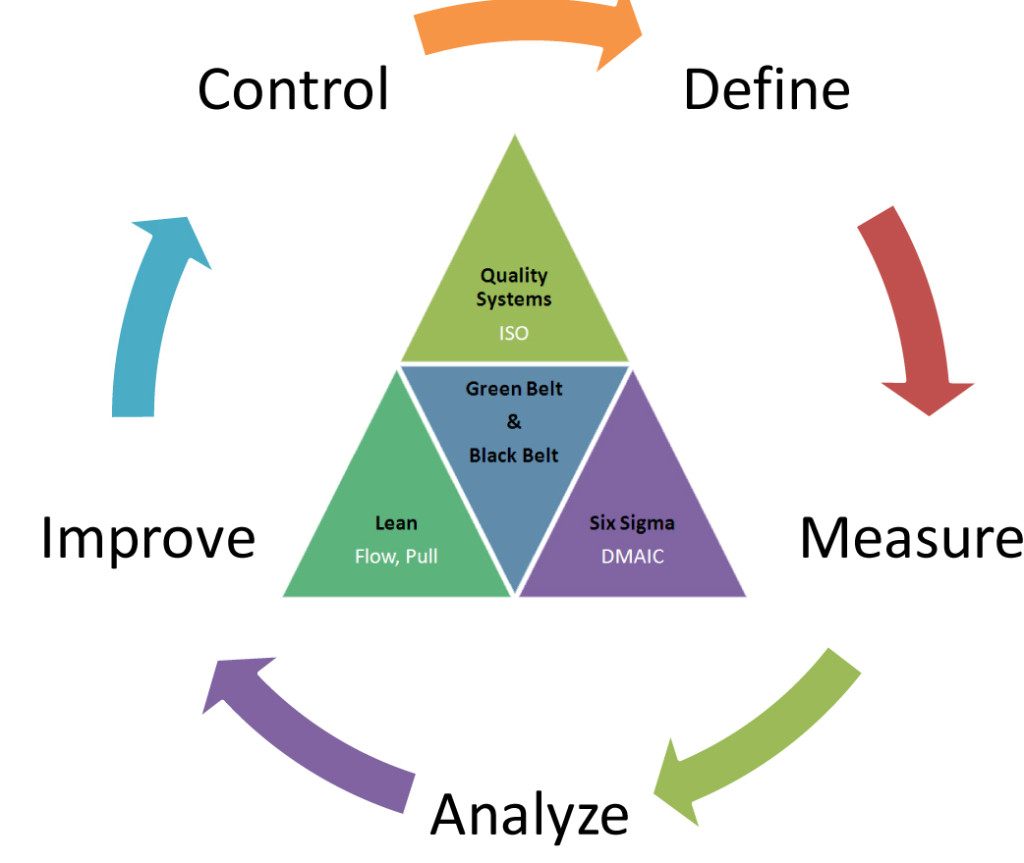

Using the SIPOC process model and understanding the differences in process levels will make it easier to manage the process of business improvement. Select a project d. It combines the tools methods and principles of Lean and Six Sigma into one popular and powerful methodology for improving your organizations operations.

Within lean philosophies we might refer to this as Kaizen. Identify the project a. They both aim to reduce waste increase customer satisfaction and increase revenue.

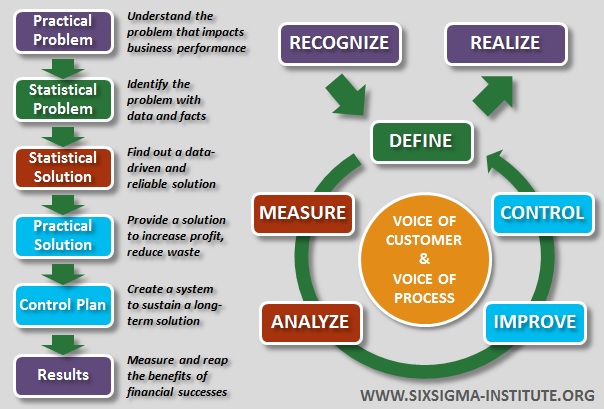

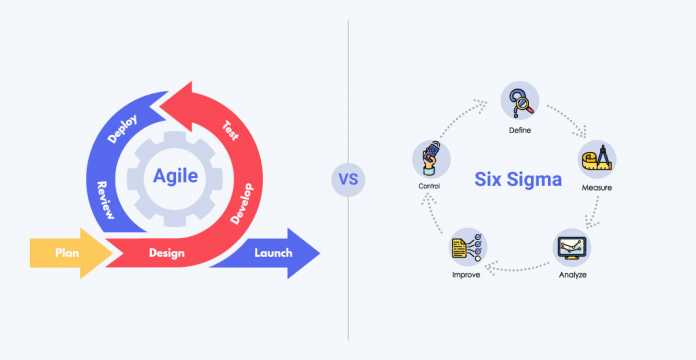

Lean and Six Sigma are both customer-focused process improvement methodologies. DMAIC is a five-step method for improving existing process problems with unknown causes. A crucial part of any lean Six Sigma process is to keep the principle of continuous improvement in mind.

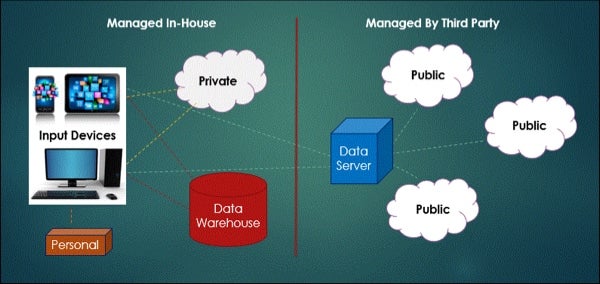

The six sigma business improvement process moves up and down the vertical levels of the organization as well as across the functional elements. They both follow the traditional quality improvement steps. As such it is at the core of the organizations strategy to meet the needs of its customers clients subscribers end-users or patients.

Lean Six Sigma is an approach to management that focuses on delivering customer value. It highlights removing wasteful steps in a process and taking the only value added steps. Lean is a systematic approach to identify and reduce project activities that are not required.

Pick a specific process or problem to improve Put someone in charge of the project. Lean Six Sigma is a Combination of Two Methodologies The approaches of Lean and Six Sigma have different origins yet they have similar goals. Incorporating statistical theory Six Sigma in a process context involves the concept that six standard deviations between the process mean and the nearest specification limit will yield just 34 defects per million opportunities.

Lean and six sigma both are two different methods. This is achieved by using careful measurement and statistical analysis to understand which levers to pull to create the desired. It is an approach supported by a framework methodologies and skills that delivers this value by emphasizing efficient operational processes and quality outcomes.

Everyone should be actively involved. Lean Six Sigma LSS is a process of solving a problem in order to maintain the quality of the project. We should look all the time at the Lean process and business results.

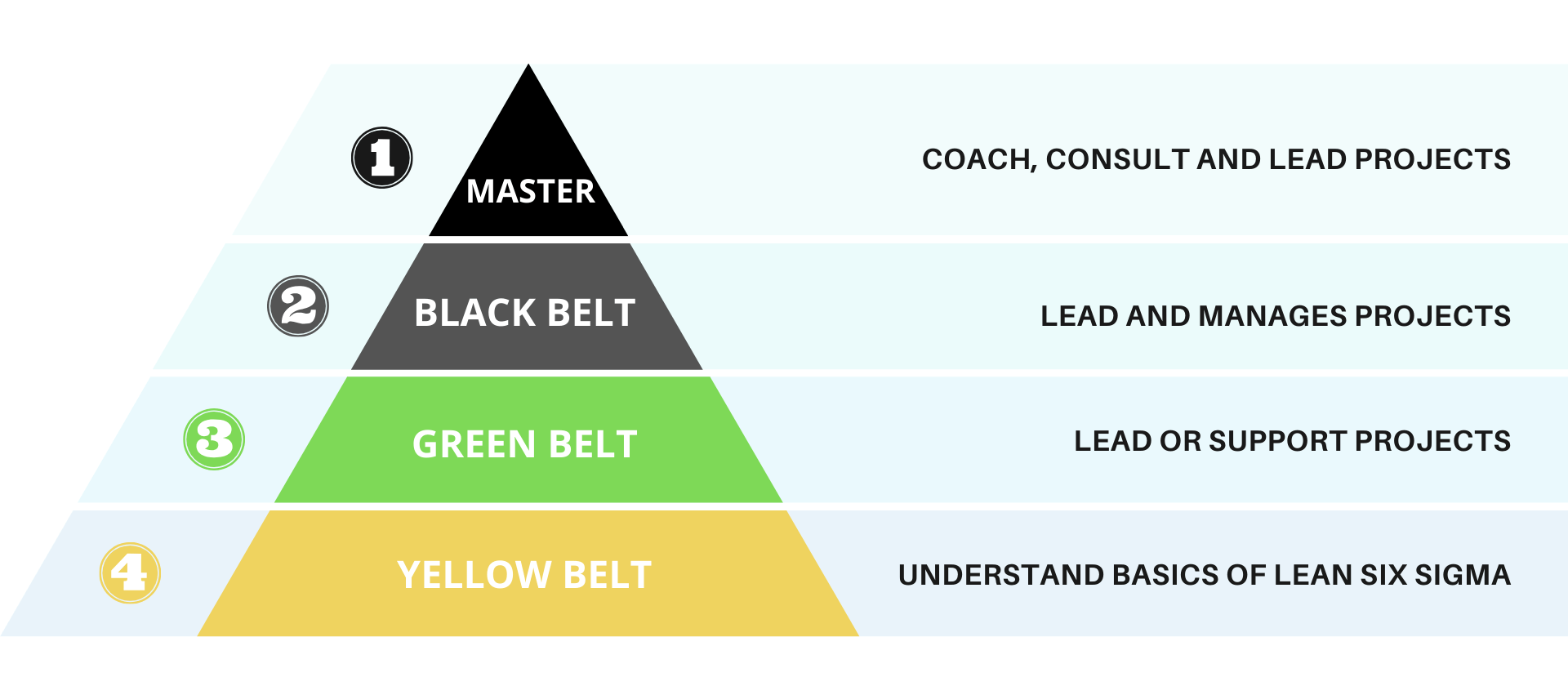

Define Measure Analyze Improve Control. 6 Sigma is a popular quality improvement methodology made famous by the likes of Motorola and GE. Three Key Elements of Lean Six Sigma.

This information could then be used to improve future performance. In order to promote continuous improvement Deming contributed the PDSA Cycle shown below. Here are some techniques to help with the Lean vision.

Six Sigma focuses on variation - reduction in the process. This process is also known as DMAIC duh-may-ik its acronym. The term 6 sigma itself relates to a level of performance where only 34 defects are produced per million opportunities.

It consists of five phases. Everyone should be thinking about constant improvement. Six Sigma originated at Motorola back in the 1980s and Lean Originated at Motorola back in the 1940s.

Is it quality improvement. Lean principles help to reduce or eliminate process wastes. Lean Six Sigma is a process improvement methodology designed to eliminate problems remove waste and inefficiency and improve working conditions to provide a better response to customers needs.

Thereby the principles of Lean Six Sigma helps to improve the efficiency and quality of the process. Lean Six Sigma combines the strategies of Lean and Six Sigma. Lean Six Sigma is a systematic approach to reduce or eliminate activities that do not add value to the process.

How are Lean and Six Sigma similar.

(1).png)