QUAL50172 LEAN AND SIX SIGMA Students Full Name. An easy way I learned at a seminar to remember the wastes they spell TIM WOODS.

Lean Six Sigma Concept Waste Page 1 Line 17qq Com

Lean Six Sigma Concept Waste Page 1 Line 17qq Com

Inventory Excess products and materials not being processed.

Lean six sigma waste. Originally there were seven wastes created by the chief engineer at Toyota Taiichi Ohno. According to Lean Six Sigma the 7 Wastes are Inventory Motion Over-Processing Overproduction Waiting Transport and Defects. It combines the tools methods and principles of Lean and Six Sigma into one popular and powerful methodology for improving your organizations operations.

Lean Six Sigma is a disciplined data-driven methodology used to eliminatereduce the process hence the product defects and waste. Motion Unnecessary movements by people eg walking. Lean Six Sigma is a process improvement methodology designed to eliminate problems remove waste and inefficiency and improve working conditions to provide a better response to customers needs.

Estimate the amount or quantity of measured waste d. Six Sigma considers this as a waste as it involves unnecessary inventory carrying costs that add no significant value to the products quality. Six Sigma 6σ is most commonly associated with hard numbers like 34 defects per million opportunities DPMO derived from the statistical roots of the doctrine in this case having control limits within 6 standard deviations of the.

There are 8 main types of waste that exist in the manufacturing of any product. Now that we know what waste is lets take a look at the 8 wastes. Lean Six Sigma is among the skills and the procedures we are very much capable and adept in doing.

Definition of 8 Wastes of Lean. I Inventory Storing parts pieces documentation ahead of requirements. Estimate the frequency of occurring c.

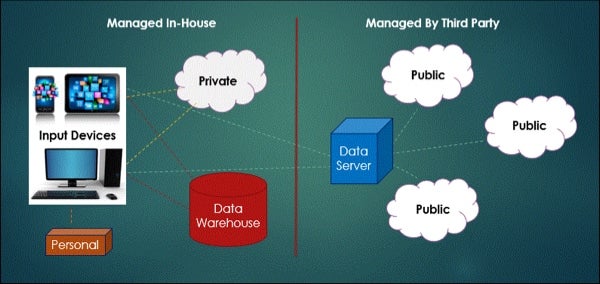

Extra Processing More work or higher quality than is required by the customer. Waste in Lean Six Sigma can be described as all the actions and steps in any existing process which does not add value to the end-user or customer. Three Fundamental Elements to Lean Six Sigma.

The application and implementation of lean six sigma is not only beneficial for the organization but also for the. M Motion Bending turning reaching lifting. The 8 different Wastes of Lean Six Sigma include transportation inventory motion waiting for time overproductionover-processing defects non-used talents of employees.

Identify and describe at least two examples of each of the 71 Wastes from your Workplace College Community or House a b. Well use the bakery example to demonstrate these wastes in practice. To avoid this you can use the Six Sigma tool known as the pull system This tool encourages you to produce only when there is a demand in the market.

To remember the 8 Wastes you can use the acronym DOWNTIME. Assignment 1 Instructions. Lean six sigma has become the most plausible methodology that can help the manufacturing organization to remove wastes and bottlenecks from the manufacturing process while meeting the environmental challenges at the same time.

Lean Six Sigma is defined as a method created to eliminate dilemmas discard waste and incompetence and enhance working conditions to produce a more favourable response to clients demands. - Defects - Overproduction - Waiting - Non Value Added Processing - Transportation - Inventory - Motion - Unused Employee Creativity Initially there were seven wastes which were defined and popularized under the Toyota Production System. Where Lean Manufacturing focuses on various types of waste reduction and process flows Six Sigma is more focused on eliminating defects and reducing variability.

To achieve Six Sigma qualities a process must produce no more than 34 defects per million opportunities. T Transport Moving people products information.

/81Zt42ioCgL._AC_SL1500_-cb7af7192107483cb9ddb8d6790bed89.jpg)