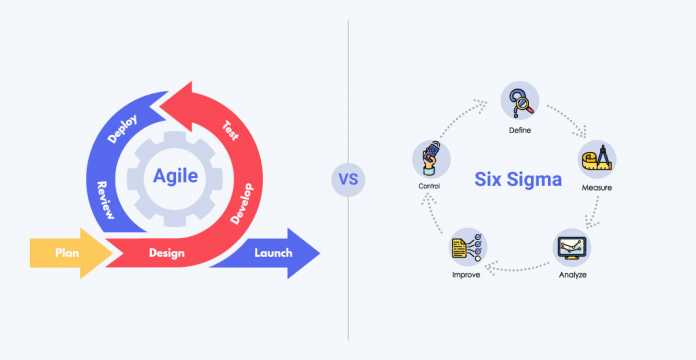

Reduce Waste Six Sigma. Read more about Lean vs Six Sigma.

Lean Six Sigma links these two approaches which produces a powerful toolkit for directing waste reduction.

Lean six sigma vs six sigma. Lean focuses on a philosophy of continuous improvement while Six Sigma is based on process improvement. Both Six Sigma and Lean Six Sigma training involve understanding complex methods and tools. The risk in randomly selecting a training and certification company is that you might not get a standard recognized training.

The main concept of lean thinking is the removal of waste while six sigma is centered towards the elimination of variation in the processes. Six Sigma is a data-driven methodology which purely works on the statistical data retrieved from a research source. Speed velocity Six Sigma.

However Lean focuses on attacking waste. Lean Six Sigma Benefit Comparison of Six Sigma and Lean Six Sigma. On the other hand Six sigma emphasis on the quality of the product by illustrating some universal principles.

The Lean was developed by Toyota whereas Motorola introduced Six Sigma. Instructors need thorough knowledge and expertise in all relevant concepts. They both seek to eliminate waste and create the most efficient system possible but they take different approaches toward how achieving this goal.

In my opinion Lean Six Sigma is the same as Six Sigma was originallyor at least the way I was taught Six Sigma by Juran Corporation. Lean is a companys method of overall organizational. Long Lean.

Operational Excellence is often used to describe Six Sigma and Lean activities but it is more related to the support system orbiting Lean Six Sigma initiatives. Six Sigma helps enterprises to cumulatively increase profits in the long run. Six Sigma Quality 34 DPMO Lean.

When to execute Lean six sigma Reduce variation Lean. In a nutshell in todays world Six Sigma and Lean Six Sigma essentially mean exactly the same thing. There are eight main areas where Lean looks to eliminate waste.

It aims to reduce the number of errors in a process by 34 or fewer defects per million items produced. The primary reason for the widespread confusion over the naming convention is because although Six Sigma began decades ago it was only when the military began implementing it that it became a household name. Lean and Six Sigma go hand-in-hand and are generally used in tandem as an approach although it is important to understand the main motivations of each.

Another difference between lean vs six sigma is that six sigma is more effective in the manufacturing and non-manufacturing sectors. The tools used by lean are based on visuals whereas the tools used by six sigma are based on mathematics and statistics. Most if not all Six Sigma programs are actually identical to their Lean Six Sigma counterparts.

Lean six sigma focuses on the way to eradicate waste from the process in the organization. The lean six sigma was developed by the company Toyota Whereas Motorola introduced the Principles of Six Sigma. In addition the six sigma concept borders around three methods.

In Lean any activity that does not add value to the end user of the product or service needs to be eliminated. Lean is flow focused but Six Sigma is problem focused. Operating Costs Six Sigma.

In simplest terms the main difference between Lean and Six Sigma is that they identify the root cause of waste differently. Lean Six Sigma Lean Six Sigma is an approach to integrating the power of Six Sigma Tools and Lean Enterprise Tools which can be applied within an organization to create the fastest rate of improvement maximize shareholder value and increase customer delight. Defects in a process.

Like Six Sigma Lean focuses on process improvement. Six Sigma vs Lean Six Sigma Lean Six Sigma simply means a program that includes lean principles in the Six Sigma Curriculum. In this lesson well compare and contrast Lean Six.

Whereas lean works better for businesses in the manufacturing sector. Lean Six Sigma and Six Sigma are two methods used for reducing waste and streamlining business processes but there are differences between them. Originally the emphasis of Six Sigma as I was taught was on measuring the process steps and this included waste rework and identifying ways to.

The primary difference in Lean and Six Sigma is that Lean is less concentrated on manufacturing but usually shapes every aspect of a business. Waiting or idle time between operations. Cost of Poor Quality Lean.

They are DMAIC DFSS and process management.