Lean Six Sigma also ensures that the manufacturing process has minimum defects thus ensuring the quality of the produced goods. This increase the velocity of.

.jpg) A Brief Introduction To Lean And Six Sigma And Lean Six Sigma

A Brief Introduction To Lean And Six Sigma And Lean Six Sigma

Lean Six Sigma evolved over the last few decades as a convergence of both these methodologies was imminent to many organizations.

Six sigma lean manufacturing. It was introduced by an engineer at Motorola in 1986 and inspired by Japans Kaizen model. We focus on the areas of greatest valuefor example using overall equipment effectiveness OEE to identify high-potential opportunities. Lean Six Sigma integrates traditional lean methodologies with a robust set of digital capabilities to transform your manufacturing operations.

They help deliver quality products and services reduce waste improve time. Lean six sigma then is a methodology that looks to combine the best of both the lean manufacturing and the 6 Sigma approaches. Visiting Address Innovation Enterprise Service University Square LU1 3JU Luton Bedfordshire.

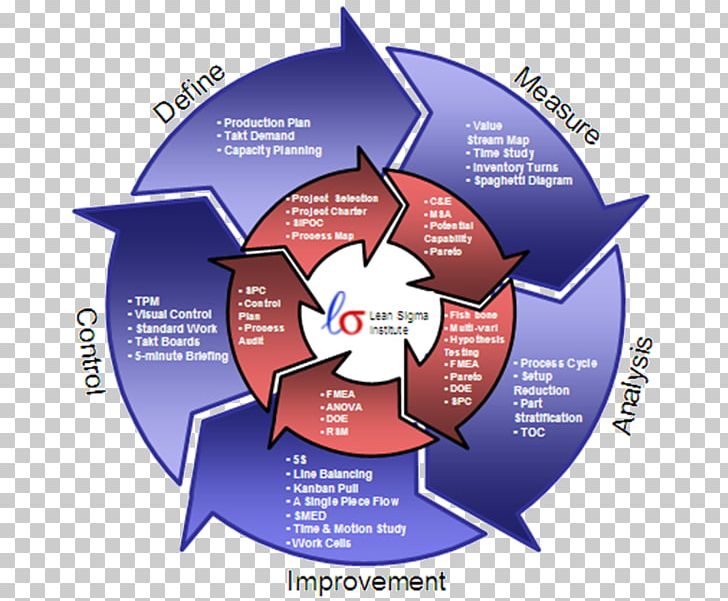

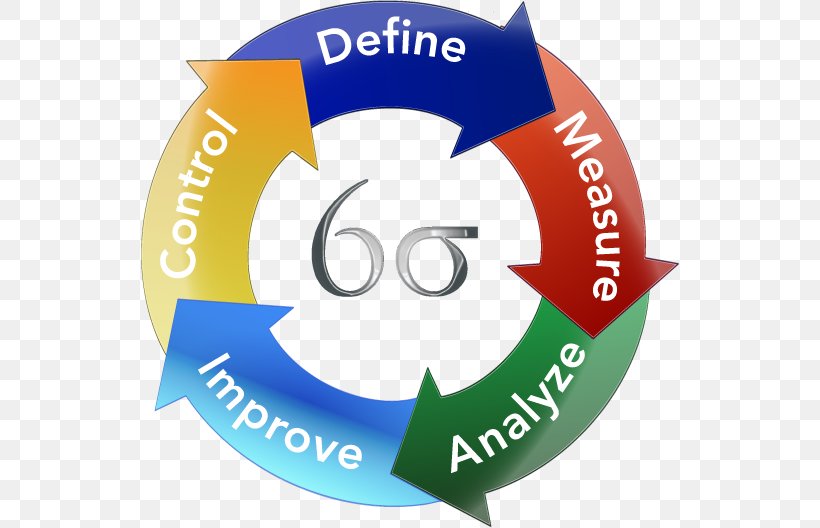

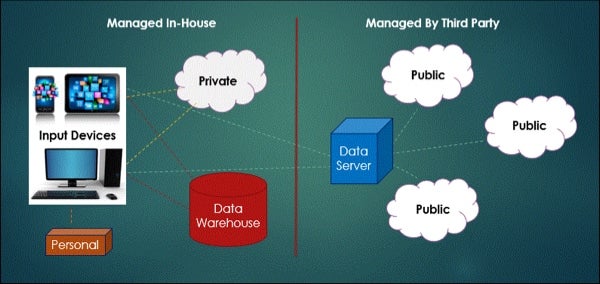

An Accredited Six Sigma Certification in Manufacturing indicates an individual has achieved a particular level of knowledge in the study and application of this methodology. Lean Six Sigma is a systematic approach to reduce or eliminate activities that do not add value to the process. Some methodologies start with the assumption that every problem has a unique or special cause and if that cause can be identified and eliminated or controlled the problem goes away.

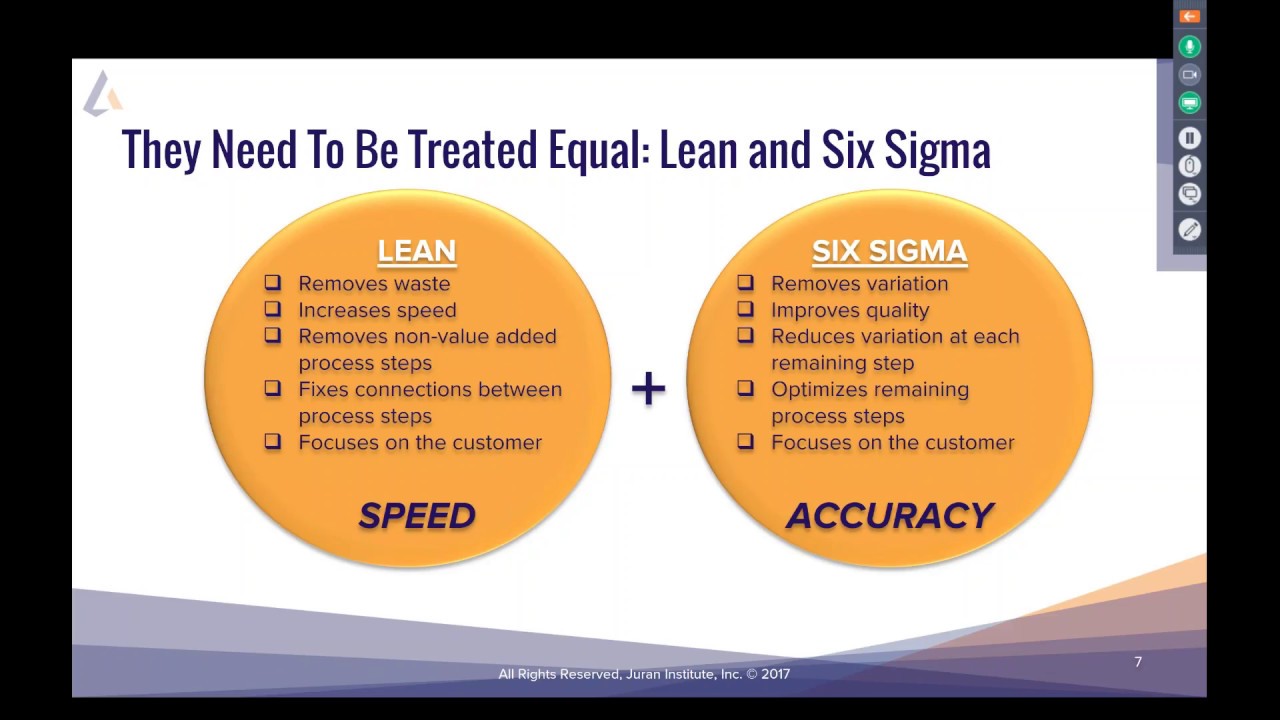

Six Sigma is a methodology that utilizes statistical tools and concepts to identify variations or defects in a process. The primary difference between Six Sigma and Lean Manufacturing is. In particular the emphasis is on obtaining the benefits of both methodologies whilst minimizing any potential weaknesses.

Lean management originated at Toyota in Japan and has been implemented by many major US firms including Danaher Corporation and Harley-Davidson. The Lean Six Sigma Company. The first priority is control which is precision and to have that precise output on a target which is accuracy.

This type of certification will make you a more valuable asset in any industry and enhance your career. Six Sigma and lean management have diverse. Six Sigma was founded by Motorola Corporation and subsequently adopted by many US companies including General Electrical GE and Allied Signal.

The lean six sigma method ensures high quality and customer satisfaction in the manufacturing. Grams are Six Sigma and lean management. It highlights removing wasteful steps in a process and taking the only value added steps.

Seven mudas are storage transportation waiting motion process defect and over production wastes. 020 3608 3527 07884 706948 infotheleansixsigmacompanycouk. What is Lean Six Sigma.

The Lean Six Sigma methodology views lean manufacturing which addresses process flow and waste issues and Six Sigma with its focus on variation and design as complementary disciplines aimed at promoting business and operational excellence. Lean vs six sigma is deployed for quality improvements. The term Six Sigma refers to tools and techniques that are used to improve manufacturing processes.

Six Sigma employs the DMAIC model Define Measure Analyze Improve Control for existing productsservices while DFSS Design for Six Sigma is deployed for new productsservice design. Taiichi Ohno father of Toyota Production System identified three broad types of wastes muda muri and mura. Lean Manufacturing focuses on finding and eliminating waste in processes to satisfy the customer.

Nevertheless lean vs six sigma both improve the business process quality of products and services and the customers experience. The benefits of Lean Six Sigma. However many lean implementations are on first waste type only with reduced corresponding benefits.

Lean Six Sigma is one of the most powerful problem-solving and continuous improvement methodologies because it identifies the characteristics of the real problem. Six Sigma uses statistics to identify and reduce variation in processes to satisfy the customer.

Lean Manufacturing Vs Six Sigma Which Is Right For You Industry Today

Lean Manufacturing Vs Six Sigma Which Is Right For You Industry Today

Lean Six Sigma Where Waste Reduction Meets Quality Improvement Inductive Automation

Lean Six Sigma Where Waste Reduction Meets Quality Improvement Inductive Automation

Waste Lean Manufacturing And Six Sigma Definitions

Waste Lean Manufacturing And Six Sigma Definitions

How To Think About Lean Vs Six Sigma Youtube

How To Think About Lean Vs Six Sigma Youtube

Lean Six Sigma The Ultimate Guide To Lean Six Sigma Lean Enterprise And Lean Manufacturing With Tools Included For Increased Efficiency And Higher Customer Satisfaction Edge James Ebook Amazon Com

Lean Six Sigma The Ultimate Guide To Lean Six Sigma Lean Enterprise And Lean Manufacturing With Tools Included For Increased Efficiency And Higher Customer Satisfaction Edge James Ebook Amazon Com

2 Interaction Techniques Of Six Sigma And Lean Manufacturing 42 Download Scientific Diagram

2 Interaction Techniques Of Six Sigma And Lean Manufacturing 42 Download Scientific Diagram

Dua Pendekatan Sistematis Untuk Meningkatkan Bisnis Lean Dan Six Sixma Shift Indonesia

Lean Six Sigma Dmaic Lean Manufacturing Quality Management Png Clipart Circle Communication Design For Six Sigma

Lean Six Sigma Dmaic Lean Manufacturing Quality Management Png Clipart Circle Communication Design For Six Sigma

Organisasi Six Sigma Bersandar Six Sigma Gambar Png

Organisasi Six Sigma Bersandar Six Sigma Gambar Png

Organisasi Lean Six Sigma Lean Manufaktur Dmaic Yang Lain Teks Lain Lain Png Pngegg

Organisasi Lean Six Sigma Lean Manufaktur Dmaic Yang Lain Teks Lain Lain Png Pngegg

Lean Six Sigma In Manufacturing A Comprehensive Review Intechopen

Lean Six Sigma In Manufacturing A Comprehensive Review Intechopen

Where Lean Manufacturing And Six Sigma Meet

Where Lean Manufacturing And Six Sigma Meet

Lean Manufacturing Lean Six Sigma Business Process Png 538x528px Lean Manufacturing Area Brand Business Business Process

Lean Manufacturing Lean Six Sigma Business Process Png 538x528px Lean Manufacturing Area Brand Business Business Process

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.